Healthy living environment from nature

Natural woodfibre softboard is a high-performance, eco-friendly timber product that plays a vital role in modern construction, design, and sustainability. Discover the benefits of fibreboard and how it supports a sustainable future through renewable resources, energy efficiency, and recyclability.

Renewable Resource

Our softboards are made from natural wood fibers, a renewable resource from sustainably managed forests, ensuring effective resource replenishment.

Environmentally Friendly

Fibreboard uses natural lignin as a binder, eliminating synthetic chemicals and reducing environmental impact.

Reducing Overall CO2

By incorporating woodfibre board solutions into their value chain, industries will reduce their products’ CO2 footprint.

Raw material preparation

Wood chips or fibers are initially processed to break them down into smaller components. This is done through mechanical and chemical methods, ensuring the fibers are of consistent size and quality.

Fibre extraction

The wood fibers are separated from the lignin and other non-fibrous components. This can involve mechanical or chemical pulping methods, depending on the desired properties of the final product.

Wet process forming

.

Natural binding

During the drying and pressing stages, the natural lignin present in the wood acts as a binding agent. This means no additional chemicals or adhesives are used, resulting in a more natural and environmentally friendly product.

Pressing and finishing

The wet fiber slurry is formed into mats or boards and then compressed under high pressure and temperature. This step consolidates the fibers into a solid, uniform sheet, which is then cut, sanded, and finished as needed.

Advantages of Fibreboard

Strength and Durability

Natural woodfibre softboards offers excellent strength and resilience. Its uniform density and smooth finish provide superior resistance to impact, wear, and deformation, making it a durable choice for various applications.

Versatility

Suitable for a range of uses, from structural components to decorative elements, Natural woodfibre softboards can be easily cut, shaped, milled, perforated and finished to meet specific design requirements.

Cost-Effectiveness

Natural woodfibre softboards are typically more affordable than many solid wood products while still offering high performance and quality. Ease of use and adaptability make them a great material by value add affordability.

Natural woodfibre softboard Properties

Produced using the wet process, our products have softboard characteristics, which enhance their acoustic and thermal insulation properties. This makes it an excellent choice for applications requiring sound absorption and temperature control.

Environmental Benefits

By using the natural lignin in wood as the binding agent, Natural woodfibre softboard production avoids the need for added chemicals and adhesives. The manufacturing process also minimizes waste and promotes the use of renewable resources. Additionally, Natural woodfibre softboards are recyclable and can be repurposed, supporting a circular economy.

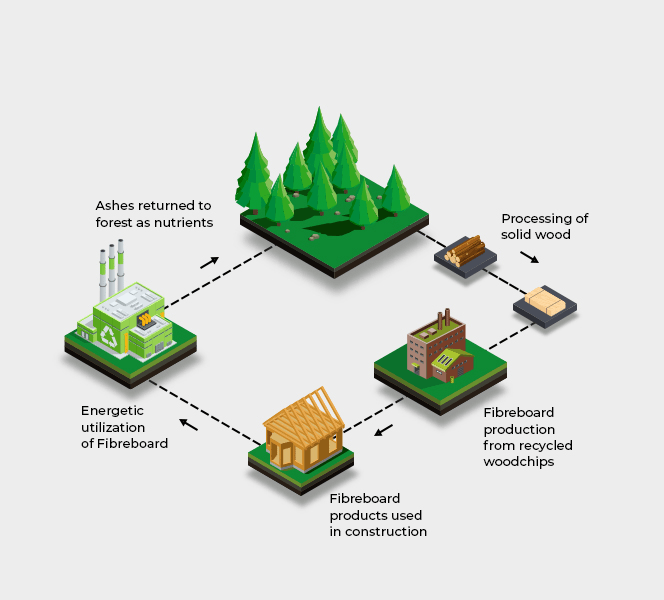

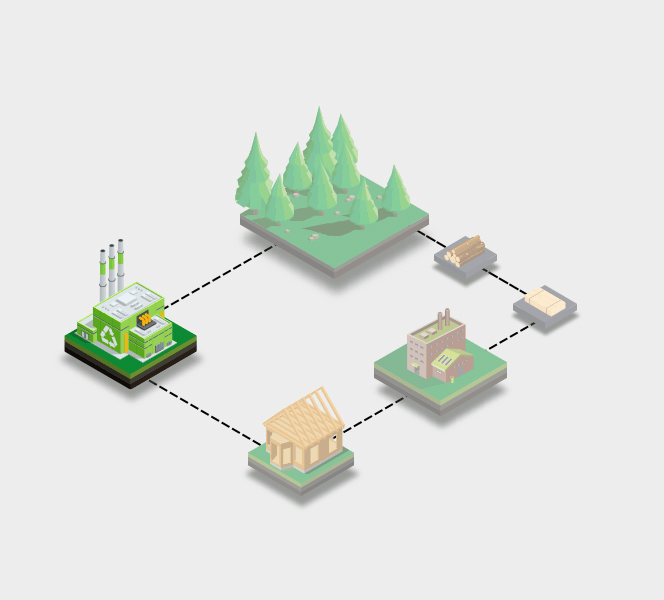

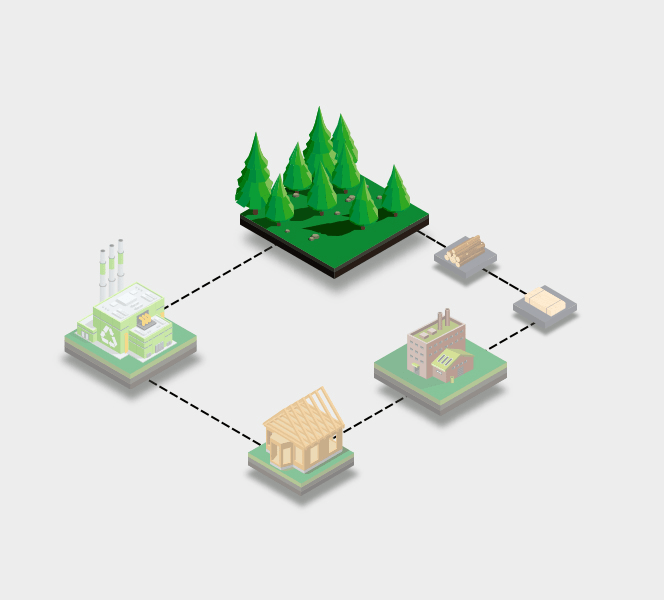

Explore the lifecycle of our fibreboard

The lifecycle of natural woodfibre softboards highlights sustainability, making it a responsible and versatile material of choice for the construction, interior solutions, and industrial packing industries on account of its renewable sourcing, eco-friendly manufacturing, recyclability, and potential energy recovery.

Raw Material Sourcing

Our timber is sourced from sustainably managed Nordic European forests, emphasizing renewable resources and responsible harvesting practices.

Manufacturing

Timber materials are processed using a wet method, with natural lignin as a binder, completely eliminating the need for synthetic chemicals or adhesives.

Use Phase

Natural woodfibre softboards provide durability in applications like construction and interior solutions, requiring minimal maintenance while enhancing functionality and aesthetics.

End-of-Life

Natural woodfibre softboards can be recycled or repurposed, supporting a circular economy and reducing waste.

Energetical Utilisation & Disposal

If recycling isn’t possible, natural woodfibre softboards can be used for energy recovery through incineration, producing bioenergy. Alternatively, their natural wood fibres decompose naturally, lowering environmental impact.

CO2 benefits

Reducing carbon footprints in the process

Natural woodfibre softboards offer a significant potential in reducing carbon footprints and contributing to CO2 sequestration. The use of renewable wood resources, energy-efficient production methods, and ability to act as a carbon sink (Embodied carbon) throughout its lifecycle make Natural woodfibre softboards a sustainable material of choice for construction and other industries.

Additionally, the insulating properties of Natural woodfibre softboards help lower the building energy consumption (Operational carbon), further supporting global efforts to reduce carbon emissions.

contact us

Get in touch with us!

- Rääma 31, 80044 Pärnu, Estonia

- +372 445 1800

- info@nordicfibreboard.com

Nordic Fibreboard Ltd OÜ

Reg. Code: 12503545

VAT: EE101652014