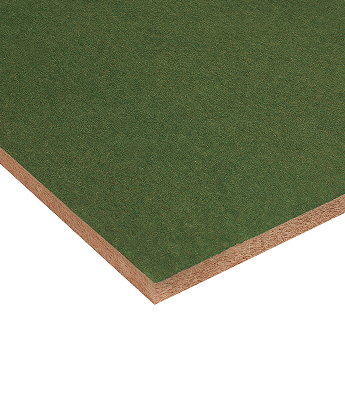

ISOplaat -

Insulation Board

Product description

Enhanced insulation, soundproofing, and structural rigidity

ISOplaat Insulation Board is a woodfibre insulation board used for additional thermal insulation, support of loose insulation material, soundproofing, and structural rigidity in interior walls, ceilings, and floors.

ISOplaat Insulation Board’s dense and porous composition offers excellent thermal insulation, blocking heat transfer and maintaining energy efficiency. Additionally, these boards provide effective sound muting, reducing noise between rooms and floors and help to regulate humidity by preventing moisture-related damage to the insulation layer.

With their natural composition and advanced design, ISOplaat Insulation Board is a smart choice for sustainable and efficient construction and renovation for both commercial and residential buildings

Easy to

Handle

Thermal

Insulation

Noise

Reduction

Natural

Design

Saving

Resources

Need a different size? Contact us and let us know.

Usage

Thickness (mm)

Width (mm)

Length (mm)

Edge

product applications

Take a look at the product application page for suggested use

Browse for insights into the versatile possibilities enabled by our product range.

Related products

find a reseller

Interested in our products? Find your closest reseller here

See our list of current resellers to find your nearest source of Nordic Fibreboard products.

contact us

Get in touch with us!

- Rääma 31, 80044 Pärnu, Estonia

- +372 445 1800

- info@nordicfibreboard.com

Nordic Fibreboard Ltd OÜ

Reg. Code: 12503545

VAT: EE101652014